MacDon Performance Stories - People PLUS Passion EQUALS Performance

The not-so-secret recipe behind MacDon's success — and the reason the FD2 PLUS delivers more to our customers.

For customers, the FD2 PLUS FlexDraper® is a brand-new addition to the MacDon slate of headers, but for those working tirelessly behind the scenes, this is a design that's been in the works for around a decade.

It's not uncommon for a product to be in the pipeline for five or seven years before it is perfected for release, but the FD2 PLUS in particular really embraced MacDon's testing culture. Techs and engineers put each piece of each product through a rigorous and thorough testing process to ensure the final product meets the company's standards and customer expectations. And by all accounts, the FD2 PLUS went through the ringer.

One of the first places the MacDon team tested the FD2 PLUS FlexDraper® header back in 2015 was Kentucky. Because the farmer they were working with grew wheat in the spring, followed by soybeans, the opportunity was there to test the very early design under harsh conditions.

So, equipped with a crate full of all the parts they might need and a modified 40-foot FD75 header as a prototype, a pair of test techs made the trip down south and got to work.

"The test techs did a ton to help that farmer out. They were operating the combine, hauling equipment around. That was important because when we got there, the farmer was loving MacDon," says Jeffrey Leachman, director of windrower-shortline operations for MacDon, who has been involved in the FD2 PLUS development process since the beginning.

"So we got down there, we hooked the prototype on, and were going to wrap up and take the weekend off basically. The farmer said, 'Hey, any combine you need, any grain cart you need, the keys are in it. You guys go test and try anything you want.' So the engineer and I were there until two in the morning. We'd hop in one combine with one header, drive, do a pass, then hop in with the prototype, and do it again. By the time we were done, we had tried every combo, filled their grain carts up, and had learned a ton on the first night."

The testing window in North America is limited, starting in spring and ending around October, so MacDon's commitment to testing takes them around the world, expanding the season and exposing the units to different conditions globally.

"We test in crops that sometimes double the yield we'd see here in North America. So we'd build a prototype from what we saw here, build it in about three weeks, shove it in a shipping container, then go to New Zealand and trial it there in January/February. It cut our development time in half," says Leachman.

"There was one time we were in the field, we learned something in August/September, modified a prototype, shipped it to New Zealand, got there in January/ February, learned from that, made a bunch of parts in Winnipeg, shipped that prototype from New Zealand to Germany, modified it again. Allowing us to run three test cycles in about 12 months, whereas it would have taken three years waiting on harvest."

But the testing isn't all done far from home; a lot of work is done near MacDon's home base in Manitoba, Canada, too. In fact, one of the definitive moments during the FD2 Plus's development took place in a field in Strathclaire, MB., when Leachman was working with test engineer David Watson. The two of them measured thousands of stems in a small square to do a statistical analysis of the current FD2 Series header compared to the newer FD2 PLUS.

"So when you do that, you'll typically get a bell curve of your distribution. So we did that on the FD2. It looked great. It was short stems, evenly distributed, and then we did it with the FD2 PLUS, and it basically proved our premise that we'd cut shorter more consistently because the bell curve had a shorter peak, and it was tighter," explains Leachman.

"So from there, we had the proof pretty much immediately after one day of testing and thousands of cut stems that we were on the right track. I spent a lot of time lying on my stomach and testing, counting beans and counting stems."

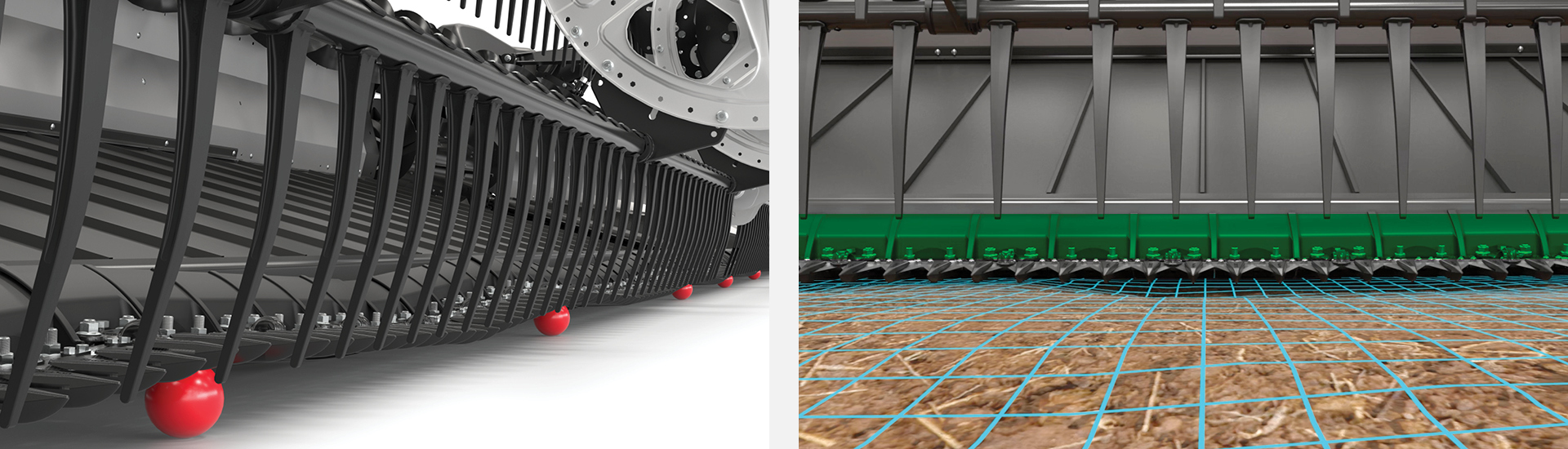

And the result of all of the trials and errors and fixes and findings is the FD2 FlexDraper® PLUS, which utilizes all the benefits of the usual FlexDraper® headers, but now includes an additional two inches of extra flex at the cutterbar and hugs the ground tighter to grab as much crop as possible (which is where the measuring of all those stems comes into play).

An especially unique aspect of the flex of this header is the reel-to-cutterbar relationship. Leachman and the team of engineers were "really cautious" about the relationship between the reel and the cutterbar as they knew they couldn't push it too far, so the question they then asked themselves was, How far could they take it? Is two inches enough?

While they weren't prepared to go quite as far as some competitors, they guessed — and then tested and proved — that those two extra inches were, in fact, enough to make a significant difference without sacrificing performance.

"Through testing, we actually found a side effect of that was that it wasn't just going down and getting an extra crop, it was that floating over stones and other field debris, too. Where other headers might be pushing or might break a section, we just floated right over top of it. So we designed it to be able to go down, but we found out that going up that little bit too, had just as big of an impact," says Leachman.

"When we came up with a winged flex header first on the 974 (FlexDraper®), that was an innovation, a first in the industry kind of thing. We progressed with that. With the PLUS's flex cutterbar, we added that little bit of extra ground following that we were missing with the wings," adds John Enns, a manager of product engineering at MacDon who worked on the FD2 PLUS.

"I spent about three years in the R&D phase, and like a lot about that design from working through it. Using springs versus pivots and hydraulics to get the flow just seemed like the right way to do it. It was a lot simpler and a lot less could go wrong with it. Things did still go wrong, but we got through those. Overall, the flex cutterbar helps us get those micro-variations in the ground that we were missing with the regular winged header."

The springs Enns mentions are called leaf springs, a simple form of spring commonly used for suspension in wheeled vehicles. In the early design stages, hinges were considered but immediately caused problems, so they pivoted to using springs instead. That simple fix did the trick. Leaf springs are compact, strong, and they stood up to all the testing from MacDon's engineers.

"They're very simple, very light. There's virtually no maintenance on them, and they're also very robust. We've never failed the leaf spring in all of our testing. That's what makes it really elegant, it solves the problem without adding a lot of complexity and weight to the machine," says Jann Garbald, another manager of product engineering who worked on the FD2 PLUS.

“They're very simple, very light. There's virtually no maintenance on them, and they're also very robust. We've never failed the leaf spring in all of our testing.”

“That's what makes it really elegant, it solves the problem without adding a lot of complexity and weight to the machine.”

"We wanted to maintain a mechanical system, and leaf springs, they're compact. They don't take a whole lot of room, but they're made of proper material and have the proper profile. It's designed to give you the amount of flex you want and maintain that neutral position, which is very important. A lot of work actually went into that," says Leachman, adding that by using a mechanical system, as opposed to a hydraulic or pneumatic one, it reduces the lag between the reel and the cutterbar.

“One thing we've always done well is with the mechanical one, you don't have to wait, it's an immediate response with our mechanical springs or mechanical linkage”

The FD2 PLUS's mechanical system leans into the "simpler is sometimes better" mantra that Leachman, Enns and Garbald all seemed to adopt during the FD2 PLUS's development process. Both pneumatic and hydraulic options are more difficult to manufacture down the line, they say, and more complexity also means more points of failure, more places for dirt to build up and more places for debris to lodge itself and cause problems. A mechanical system is simpler on all fronts, and if it should happen to fail, it's much easier to fix.

And "simple but effective" is a description that can be applied to the FD2 PLUS as a whole, not just the springs. Leachman, Enns and Garbald all insist that while two inches of extra flex may not seem like much, it makes all the difference to the farmers in the field. Enns says they worked with several farmers, and the feedback was positive.

"Any crops where the seed is so low to the ground, you just get that little bit extra. With farming, every bean you leave in the field is lost profit. It's right off the top. That's why I think it's worthy to pursue some of these concepts," says Enns.

“Any crops where the seed is so low to the ground, you just get that little bit extra. With farming, every bean you leave in the field is lost profit.”

"Initially, you look at it and you're like, plus or minus an inch, that's not going to make any difference. But then, when you're in a field and you actually see it, it's quite impressive. In lentils, where the crop is really low to the ground, it's very clear where FD2 PLUS was cutting," adds Garbald.

“In lentils, where the crop is really low to the ground, it's very clear where FD2 PLUS was cutting”

"It was really just getting the data right to prove there is a benefit, and specifically in lentils, peas and beans, it was quite rewarding having it in the field and actually being able to quantify the improvement that you saw. Especially, any of those crops when conditions were very challenging, it was very clear in what parts of the fields whether it was our current FD2 or a competitive head – generally we do quite a bit better than the competitive heads, too – but to go another level… There were some fields of lentils, you'd walk through them, and just that extra inch being able to go down was able to capture it all. I thought that was really rewarding to see; now that's crop that's in the bin and not on the ground."

“I thought that was really rewarding to see; now that's crop that's in the bin and not on the ground."”

One word that is thrown around both at MacDon and about MacDon is "innovation." The term means different things to different people; for Garbald, innovation is MacDon's ability to keep finding ways to both improve existing products or develop new ones so that customers can get the most out of their investment in a MacDon product. For Leachman, MacDon's innovation is in the process; it's about who they hire, how they train and teach them about the product, and how the company encourages trial and error and outside-the-box thinking to get more value, reliability, and performance to the customer.

The FD2 PLUS embodies both these definitions of innovation; from its earliest days until release, the FD2 PLUS felt the benefit of the testing culture MacDon has instilled in its teams, while also, as always, prioritizing the customer experience and results. And everyone who had a part in its development, seeing the tangible, positive outcomes of their work, is the point of it all.

"You make a change to the machine and then you look at how much you end up with in the bin," says Garbald. "When you see that your change helped improve it, even if it's just a few percentage points, then when you look at the big picture, that's a significant impact for all of our customers."

Visit our product page to learn more:

FD2 PLUS Series FlexDraper® Header

Additional resources:

Owners Resources

MacDon Dealers

MacDon Performance Parts

Other Stories

MacDon Performance Stories - C Series - Peterson Farm Bros

The Peterson Farm Bros are fifth-generation farmers turned YouTube sensation. This past corn harvest, the MacDon C Series had them smiling from ear to ear.

MacDon Performance Stories - FD2 PLUS: Powered by Passion. Built to Perform.

MacDon’s team delivers another farmer-focused innovation, earning AE50 recognition along the way.

MacDon How To - FD2 PLUS FlexDraper® Header - Cutterbar Lockout

Christian walks through how to switch the flexible cutterbar on an FD2 PLUS from flexing mode to rigid mode, and then back into flexing mode. Rigid mode may be useful for maintaining a more consistent stubble height in off-the-ground cutting.

Don't Miss Out!

Get MacDon news, offers, product announcements, and more directly to your inbox.