FD75 FlexDraper® Headers for Combine

TRUE FLEXDRAPER® NO COMPROMISE

The original FlexDraper® , MacDon's FD75 continues to advance harvesting technology. It features a fixed reel-to-cutterbar relationship and the smooth, consistent, heads-first feeding that makes the FlexDraper® a harvesting performance legend. As the ultimate performance modification for your combine, this machine can significantly boost productivity in any crop and any harvesting situation. That's why more top producers and custom harvesters trust the FlexDraper® with their harvest.

Product Highlights:

- MacDon's Active Float System allows the header to conform to the ground with minimal ground pressure for an even cut every time.

- On-the-go control of ground pressure, cutting height and fore-aft header tilt.

- The patented flip-over action of our reel promotes smooth crop flow.

- Tight draper seals help prevent debris build-up and downtime.

- The proven durability of MacDon's Wobble Box knife drive.

- Adjustable sickle speed, knife reverser, and precise draper speed controls keep you cutting.

- MacDon Draper Headers are designed to fit on all major brand combines. This multi-brand compatibility, along with MacDon's performance reputation, means your investment will hold its value until it's time to upgrade your header.

Documents

Related Performance Stories

Products mentioned in this article: FD75 FlexDraper® Headers for Combine “It’s safe to say...

Products mentioned in this article: FD75 FlexDraper® Headers for Combine “Before we started using FlexDrapers...

Products mentioned in this article: FD75 FlexDraper® Headers for Combine “Spending less time harvesting means...

Products mentioned in this article: FD75 FlexDraper® Headers for Combine “Going to MacDon’s draper...

With our previous flex-head we would try to maintain 100% engineload, but we were always down in the 50%, 60%,70% range. Now with the FD70 we’re not only able to attain 100%, we are also cutting 3 to 4 MPH (4.8 to 6.4 km/h) faster, and 4' (1.2 m) wider with each pass.

Find out more about FD75 FlexDraper® Headers for Combine

We have run over 10,000 acres of crop in just 2 seasons through our MacDon FlexDraper with no issues. The darn thing just works.– Jim and Tracy Zeorian, Manley, NE

We are so impressed with our MacDon FlexDraper. It has instantly given our combine a 15% boost in capacity.– Christian Kirchner, La Salle, MB

The MacDon FlexDraper is the best investment I have made for my farm in the last 20 years.– Billie Danner, West Liberty, IA

PRODUCT FEATURES / PERFORMANCE OPTIONS

True Multi-Crop Header

True Multi-Crop Header

The FlexDraper® switches easily from flex to rigid applications with the quick flip of a lever. Harvesting cereals, oil seeds, beans and just about any crop in any condition makes the MacDon FlexDraper® a true multi-crop header.

Flex-Float Technology®

Flex-Float Technology®

MacDon's Flex-Float Technology® is what makes the FlexDraper® perform so well. The flex advantage comes from a fixed reel-to-cutter bar relationship, and the float advantage comes from instant float response of the header. See the next page for more details.

Reel To Cutterbar Relationship

Reel To Cutterbar Relationship

The MacDon FD75 FlexDraper® features a fixed reel-to-cutterbar relationship. A small critical gap between the reel fingers and the cutter bar is maintained at all times, even at extreme flex. This small gap ensures smooth, consistent, heads-first feeding of the crop over the entire width of the FlexDraper® .

Active Float System

Active Float System

Two sets of coil springs on the CA25 support up to 97% of the header weight, which allows for instant float response of the header over rolling and uneven terrain. In addition to the already amazing flex action of the FlexDraper®, the Active Float provides 4.8° of lateral float and 7" (178 mm) of vertical float independent of the combine feeder house. This prevents the header from getting caught up in bumpy fields, which leads to uneven cutting and unnecessary dirt ingestion. MacDon's Active Float System keeps our headers true to the ground for a nice, even cut and ensures smooth, consistent, heads-first feeding to the combine.

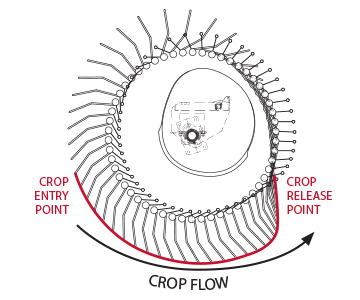

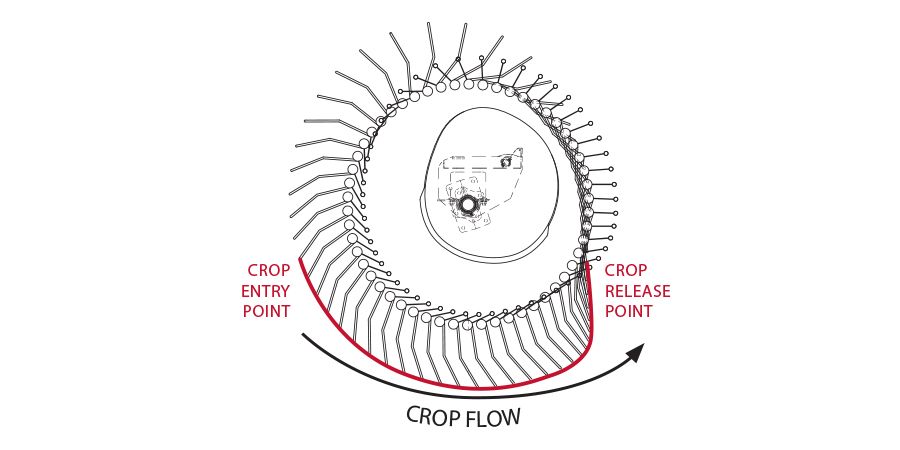

Reel Performance

Reel Performance

MacDon's patented pick-up reel has been engineered to deliver outstanding performance. The unique movement of this reel and the reel fingers confidently picks up and gently places crops onto the draper. Along with 4 cam positions, header tilt control, and fore-aft reel positioning, this reel can be adjusted to meet the toughest harvesting challenges and helps to deliver smooth, consistent, heads-first feeding of the crop to the combine.

True Ground Following

True Ground Following

The MacDon FD75 is a floating, three-section flexible header with a split reel. This allows the entire header frame, cutterbar, and reel to follow ground contours as a unit, flexing up to 10" (245 mm) on either end while maintaining a close reel-to-cutterbar relationship. This unique three-section design lets the FD75 FlexDraper® deliver smooth, consistent, heads-first feeding to the combine, even at extreme flex.

Cutterbar Poly

Cutterbar Poly

This kit is a compression molded component that has very high wear characteristics. It is used when cutting low podding crops like soybeans, lentils, or other lodged crops. The smooth design characteristics make this kit ideal for muddy harvesting conditions by reducing the likelihood of mud building up on the cutterbar.

This kit is available for all header sizes.

Advanced Draper & Seal Technology

Advanced Draper & Seal Technology

MacDon’s draper system features heavy-duty drive components designed to handle the heaviest crop loads. The V-guide draper tracking system keeps the drapers tracking perfectly, moving the crop quickly and constantly across the drapers. MacDon double V-guide drapers are reversible for twice the amount of in-field use.

Upper Cross Auger Option (Combine)

Upper Cross Auger Option (Combine)

Attached in front of the back tube, the upper cross auger improves feeding of the crop to the center in heavy, bushy, and high-volume crop conditions.

Transport & Stabilizer Package Option

Transport & Stabilizer Package Option

This kit will allow you to transport your draper header from farm-to-field and then quickly switch to field Stabilizer Wheel position by one person. The Transport Package is a simple self-supporting unit with very little hitch weight for simpler hitching. The transport tow pole is a two piece unit that requires no tools to assemble / disassemble and stores on the back tube of the header during harvesting operation. The Stabilizer Wheel application is ideal for cutting off the ground, by stabilizing the header in undulating ground conditions.

This kit can be used on 30’ (9.1m) and larger headers.

FD75 FLEXDRAPER SPECIFICATIONS

| Size/Cutting Width | 30 ft (9.1 m) | 35 ft (10.7 m) | 40 ft (12.2 m) | 45 ft (13.7 m) | |||

|---|---|---|---|---|---|---|---|

| Weight - Single Knife Drive1 | 6746 lb (3060 kg) | 7167 lb (3251 kg) | 7589 lb (3442 kg) | - | |||

| Weight - Double Knife Drive2 | - | - | 7789 lb (3533 kg) | 8218 lb (3728 kg) | |||

| Knife: Type / Drive / Speed / Guards | Single or double knife / Hydraulic, MacDon design enclosed oil bath wobble box(es) / 1050 to 1400 SPM, varies depending on header size / Pointed DHT (double heat-treated), strong, mud resistant profile | ||||||

| Reel: Type / Drive / Speed / Fingers | Model PR15 pick-up reel, 2-piece (double), flip-over design, cam-leading finger control / Hydraulic / 0 to 67 RPM varies depending on combine model / 11 in (279 mm) length, wear-resistant HD plastic, 6 in (152 mm) spacing | ||||||

| Conveyor: Type / Drive / Speed | 41.6 in (1057 mm) width, reversible 24 oz (680.4 g) rubber skim-coated drapers, double V-guide with tracking, integral seal on leading edge / Hydraulic / 0 to 464 ft/min | ||||||

| Standard Features | Adapters for most current model combines, hydraulic fore-aft reel positioner, hydraulic header tilt, cutterbar poly wear plates, auto-header height with header angle and ground pressure indicators | ||||||

| Field Installed Options | Upper cross auger recommended for tall bushy crops, stabilizer wheels, slow-speed transport with stabilizer wheels and other specialty option kits | ||||||

* Please note: All listed weights are approximations and will vary depending on header configuration. Check with your dealer for combine ratings. Weight includes CA25 Combine Adapter. The CA25 Combine Adapter weighs approximately 2050 lb (930 kg); this number varies by combine model.

CA25 COMBINE ADAPTER SPECIFICATIONS

| Center Draper | Feed Auger | |

|---|---|---|

| Size | 78.7" (2000 mm) width | 65.3" (1660 mm) width |

| Weight |

Approximately 2050 lb (1089 kg) varies by combine model |

|

| Type |

Self tracking rubber coated polyester fabric |

Floating auger, mechanical drive (reversible), removable retracting fingers with full-retraction when reversing |

| Speed |

350 to 400 ft/min (107-122 m/min) |

150 rpm, varies with combine model |

|

Header Flotation: Type / Vertical Range / Lateral Range (tilt) |

2 pairs coil springs, independent adjustment (single point at either side of adapter), transport lock-out / 7 in (178 mm) / 4.8 degrees |

|

Available for most current model combines.